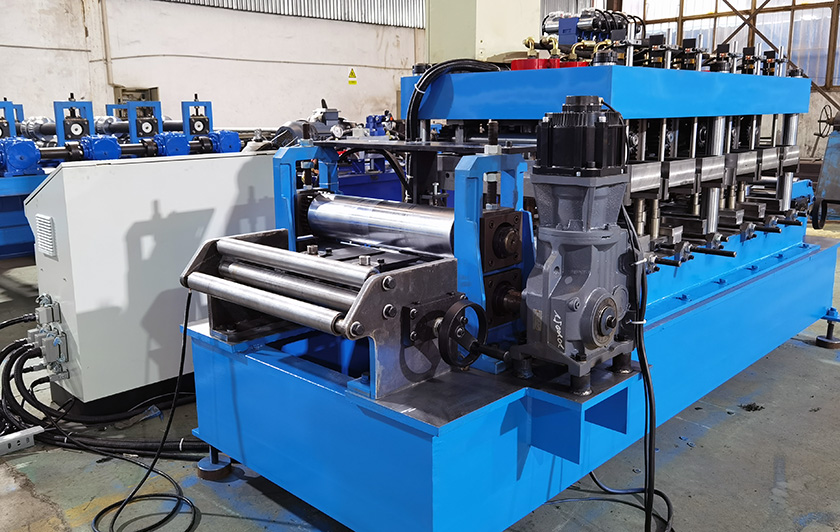

CZU Purlin Roll Forming Machine

The NTK-CZU-200AF Purlin Roll Forming Machine is used to produce variuous C/Z/U profiles, the main machine is driven by gearbox and the universal cutter adopts fly cut. Its speed is designed as 30-40 m/min including cut, with automatic stacker.

All motors, PLC, control panel of this line adopts Siemens brand.

Fully Automatic C Z Purlin Machine (NTK-CZU-200AF)

C/Z/U interchange and size change of NTK-CZU-200AF all are controlled by PLC and operated on control panel, fully automatic. Also we have other types, such as NTK-CZ-300A fully automatic CZ purlin machine, NTK-CZ-300 semi automatic CZ machine, and NTK-CZ-400 for 400mm/4mm purlin machine.

1. Raw material: galvanized sheet, black sheet; 1.5-3.0mm

2. Product size: 80-200/ 30-60/10-20mm (web/ flange/ lip)

3. Machine speed: 30-40 m/min (fly cut, gearbox drive)

Fly Cut Purlin Roll Forming Line Main Components:

Double Head Hydraulic Uncoiler

1. Type: Double head hydraulic uncoiler with coil car

2. Load capacity: 6T

Servo Motor Feeding 6 Stations Pre-punch

1. Punch molds: 6*2, it can punch maximum 12 different holes each time.

Purlin Main Machine

1. Roller material: GCr15 with heat treatment, polishing and galvanizing.

2. Main motor: Siemens motor

3. CZ Interchange: interchange between C and Z purlins controlled by PLC and set through touch panel.

4. Size Change: size change also controlled by PLC and set through touch panel, continuously adjustable.

5. All motors, PLC, control panel are Siemens brand.

Fly Cut

1. Adopts fly cut, cutting while machine not stop.

2. Universal cutters for all purlin sizes.

3. Cutting length, cutting pieces, and punching are controlled by PLC.

As the leading and biggest C&Z Purlin Machine manufacturer in China, on average we have delivered 180-200 sets Purlin Machines each year in the past 5 years, also we are the only factory to supply fully automatic type in China.